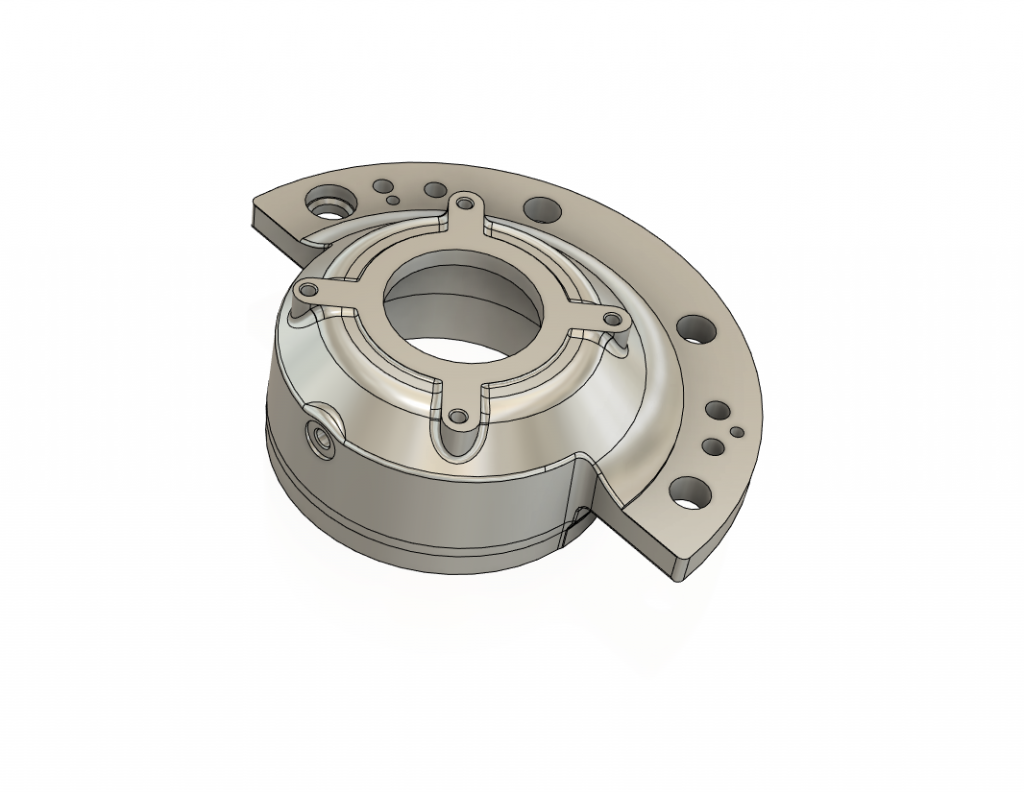

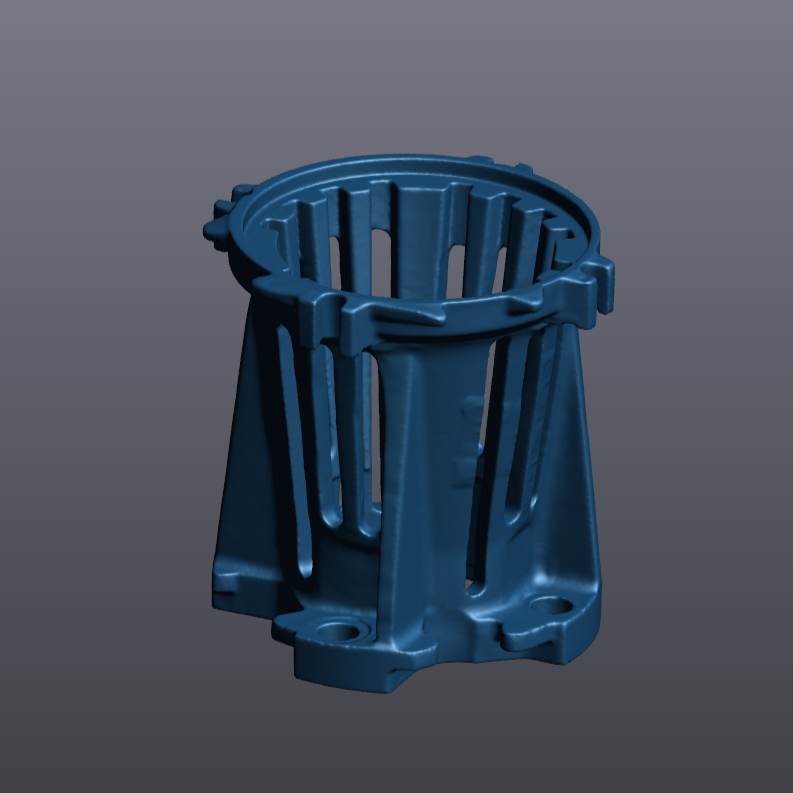

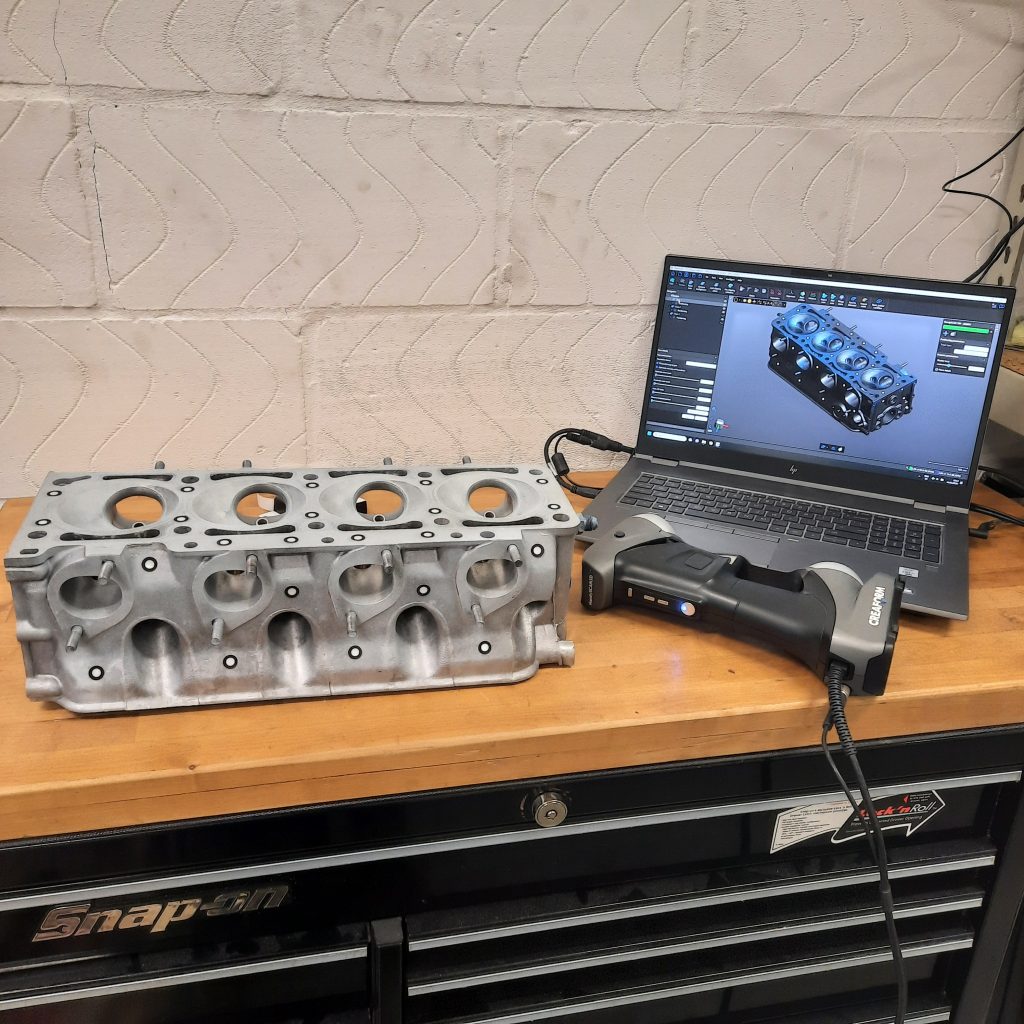

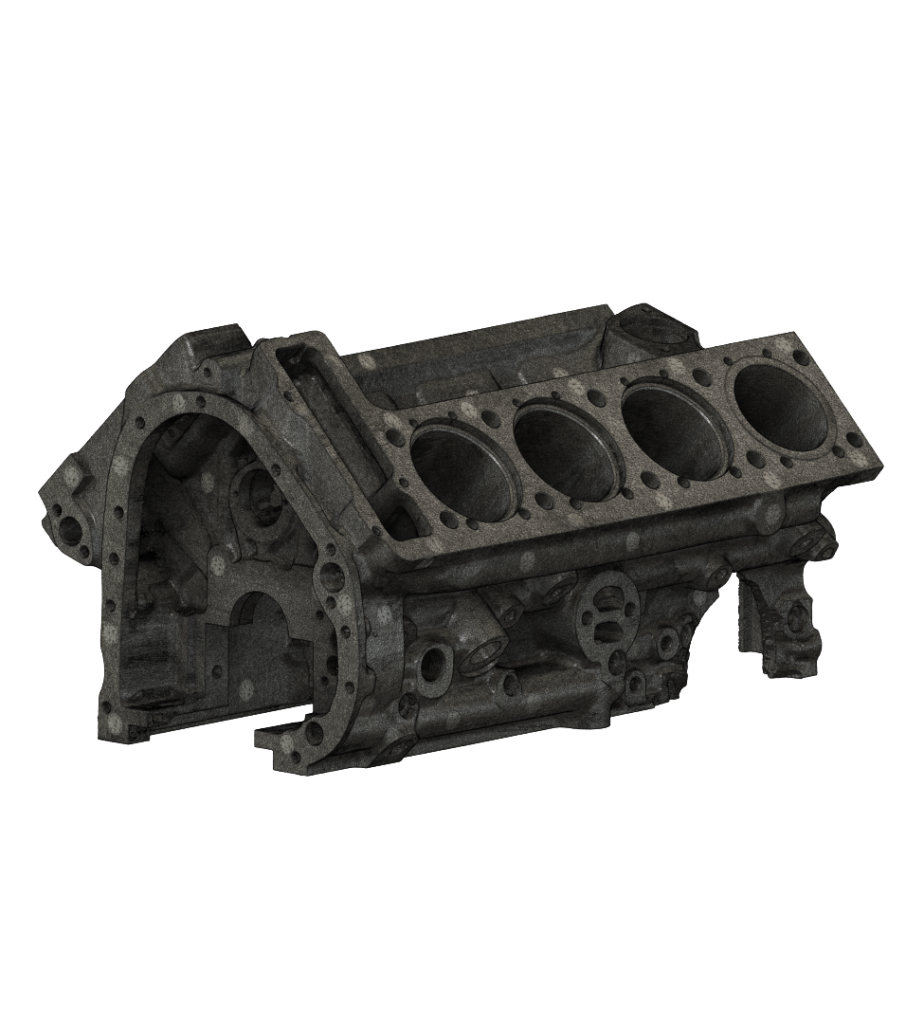

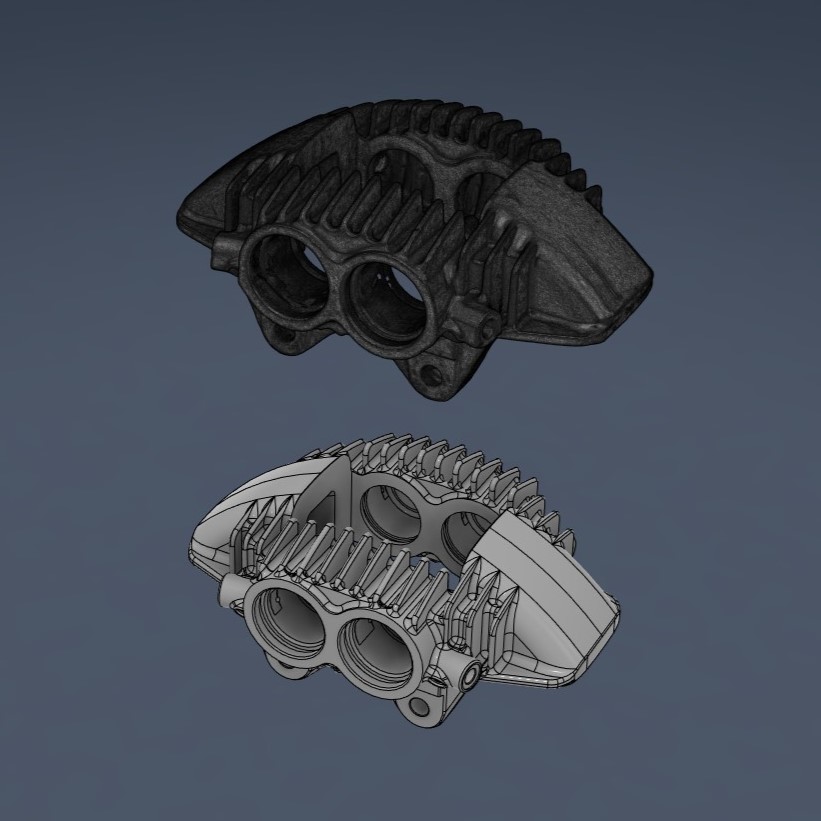

Utilising metrology grade laser scanning technology we are able to capture 3d data of physical parts of which can be turned into usable CAD Data for remanufacture or Finite element Analysis (FEA) for optimisation in performance.

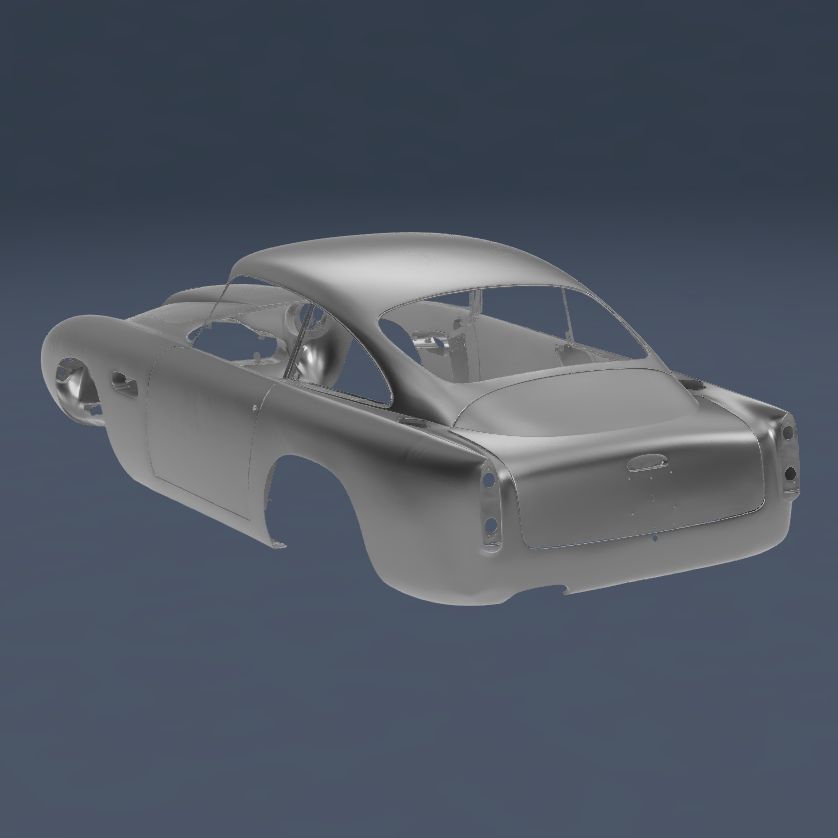

Such applications for this service is in historic racing, where most components are no longer available to buy off the shelf. Hard to source components can easily be scanned, modelled, and drawn ready to be made the latest manufacturing technologies.

Being able to capture these rare components digitally not only increases the longevity and value of the historic cars but comes with the ability to improve performance. By applying modern engineering techniques such as FEA and CFD, one can optimise component performance, whether that be increased part life or weight optimisation, ultimately improving vehicle performance.

Of course, this service can be applied to any problem where component availability or digital data is limited.

Quality control and Inspection

Our laser scanner is accurate to +/-0.030mm meaning that the 3d data extremely reliable. This allows us to use this for quality control to inspect fresh components to specified tolerances against the CAD model.